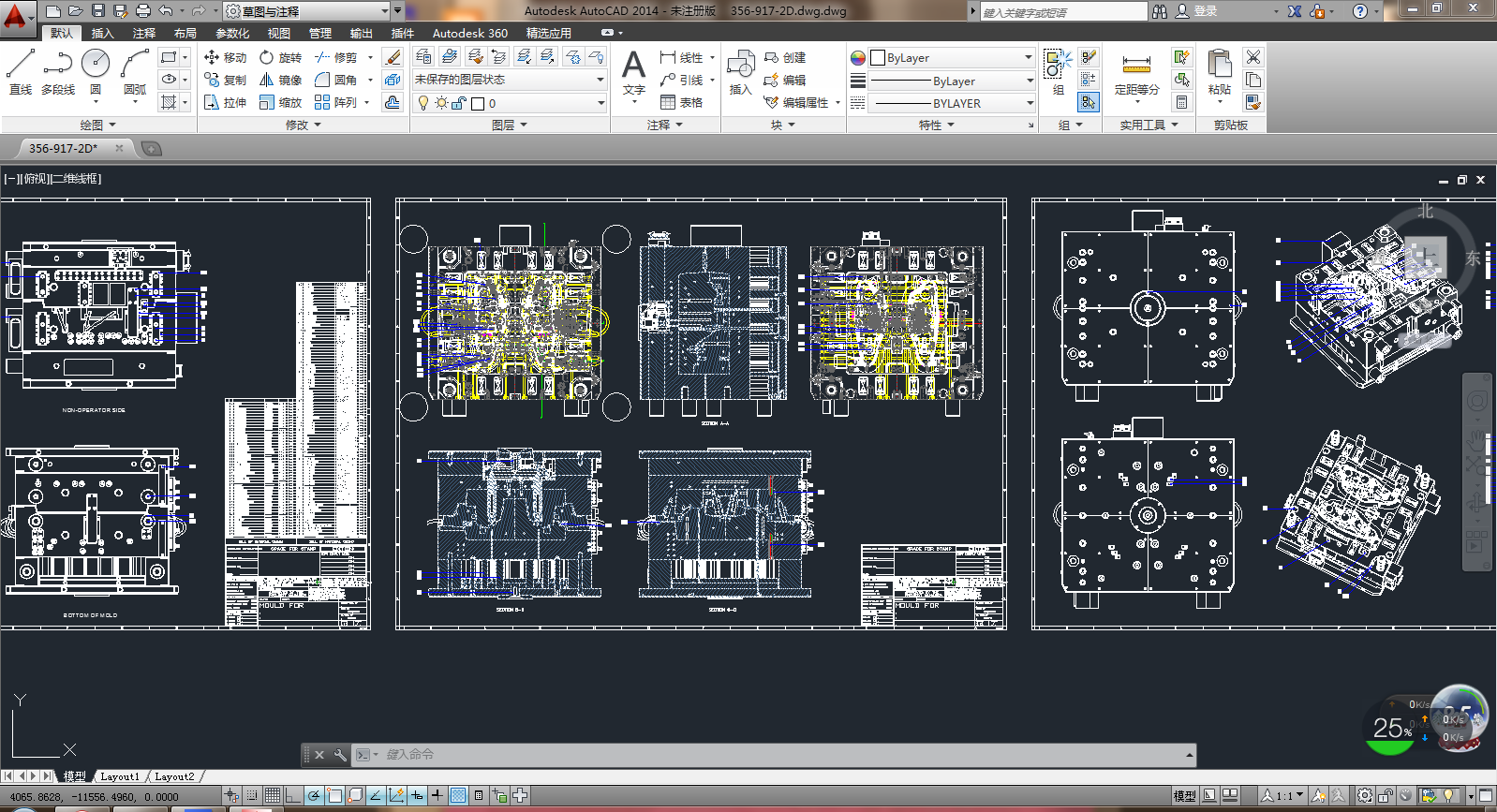

More than 15 experienced engineers use professional software to design molds in accordance with

customer’s requirements and provide package service from concept to production. Engineering

department stands the most important role in making long life and high precision molds.Our engineering

team is composed of well educated and experienced professionals who are able to make 3D and 2D

mold designs efficiently. Here it is the perfect combination of design and manufacturing technology and

experience.

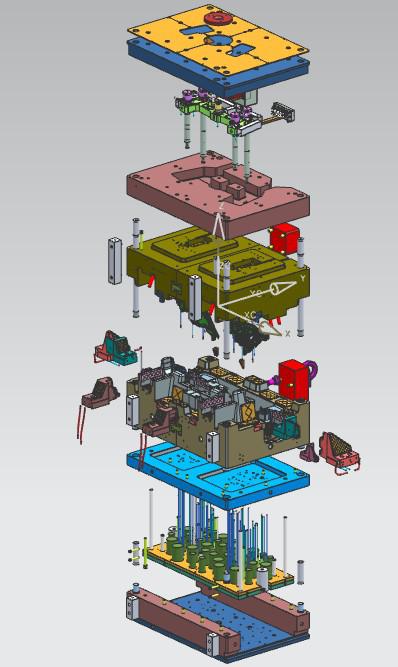

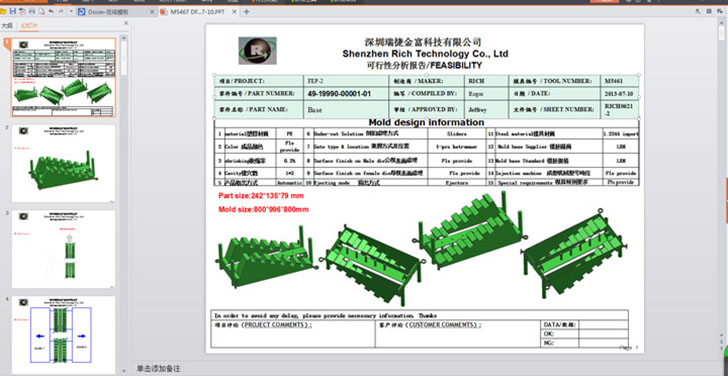

The design of mold structure is the key of mold quality. We use CAD, CAM and CAE to carry out our

mold design. In addition to the traditional design concept, we use advanced 3D software to stimulate

mold structure,disasseemble and assemble, and find solutions to the possible problems such as

shrinkage, deformation, difficult filling, and provide timely corrections during the design phase, but

also improve work efficiency, thereby creating high-quality, high standard mold.

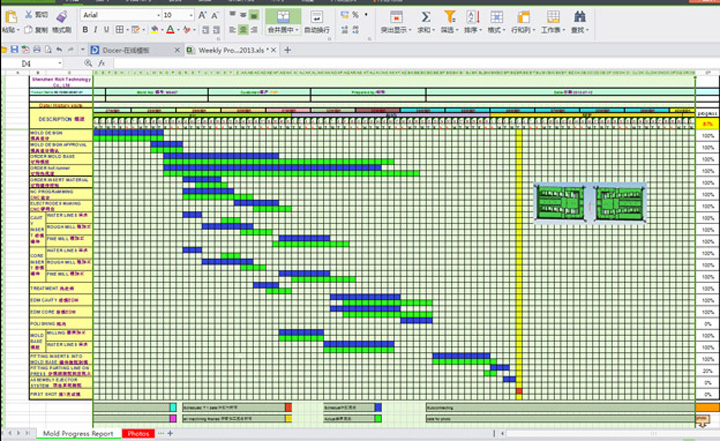

Moldflow Analysis

Use mold flow analysis system, structural analysis system and finite-element preprocessing system

to analyze the product in multi-imensions, and study the molding flow in injection mold to find out any

design defects. In this way perfect the runner design, shorten the tooling lead time and help to predict

any hidden issues in order to build the mold at a higher quality but lower cost.