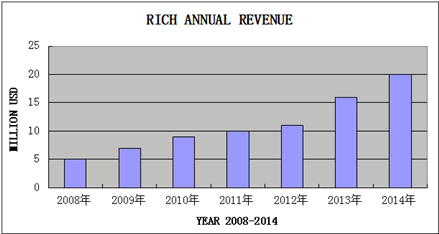

Thanks to company’s investment of funds and technology, our business enjoys a very good momentum

of development and our annual revenue keeps increasing.

RICH embraces and deploys continuous improvement philosophies and shares best practices globally,

including Lean Manufacturing, Kaizen and 5S.

Kaizen

RICH invests significant resources for continuous improvement, including RICH's own Kaizen training

program which helps employees at all levels identify opportunities to enhance operations. RICH also

has an employee-driven program designed to optimize manufacturing processes and reduce waste

and cost.

5S

5S is a key component and foundational element of lean manufacturing and has been embraced and

applied throughout RICH’s operations.

5S focuses on having visual order, organization, cleanliness and standardization. The principles underlying

5S at first appear to be simple, obvious and common sense; and they are, but without a formal 5S program,

many businesses ignore these basic principles.

The 5S's are:

· Sort - keep what is needed and discard the rest

· Straighten - organize, identify and arrange those items that are needed

· Shine - clean and keep things in order

· Standardize - develop a systematic approach to maintain

· Sustain - developing the culture and discipline to maintain what has been accomplished